Olive trees are present in the eastern part of the

The historical development of olive trees is attributed to its cultivation for oil extraction. Archaeological evidence indicates that olive oil production began in the Neolithic period (8300 to 4500 BC), coinciding with the agricultural revolution that took place 10,000 years ago. For example, olive kernels and tools for olive oil production were found in the coastal areas near

This overview focuses on the olive economy as part of the industrial heritage of Palestine in the nineteenth century. In that period a large number of manual iron screw presses (iron presses) were acquired and integrated into the old press buildings in many villages and cities, and many of them are still found within abandoned presses, serving as tangible evidence (material archive) of the machinery used in the olive oil extraction process. They also document the prosperity of the village and its connection with the Palestinian city during that significant period in modern Palestinian history. Iron presses have been neglected in archaeological research, unlike ancient techniques that also contributed to olive oil production throughout history. Technologies that preceded the use of iron presses have been extensively documented by many archaeologists interested in this region. However, the iron screw presses also constitute a tangible heritage of a rural industry that contributed to the prosperity of villages and especially Palestinian cities, in the nineteenth century. They represent an industrial legacy, because their primary role was the production of goods intended for consumption and trade. This legacy also speaks of “industrial buildings” and significant landmarks that strongly characterized the architectural landscape of Palestinian villages.

Trade

Olive oil was an integral part of the economy of the Ottoman Empire . In 1863, the investment policy in this sector led to the planting of 500,000 olive trees annually to increase production. (The olive tree takes ten to twelve years to bear fruit.) Foreign trade was the main factor in the development of olive oil production and the soap manufacturing sector.

The proto-industrial sector in Palestine can be dated to the time of

The production of olive oil was intended primarily for commercial purposes, especially for export. Production was controlled by a central authority that collects taxes as a share of locally produced olive oil. Another decisive factor in the expansion of olive oil exports was the Ottoman regime's decision to reduce export duties. In 1861, tariffs were reduced from 12 percent to 8 percent. Thereafter, this rate saw an annual decline from 1 percent, eventually reaching only 1 percent by 1869. Table 1 shows the growth of exports of olive oil and soap from the port of Jaffa between 1857 and 1882.

Table 1

Average Annual Exports from the Port of Jaffa, 1857–1882

|

Year |

Olive oil (in Oqqas) |

Value (in piasters) |

Soap (in Oqqas) |

Value (in piasters ) |

|

1857 |

20,000 |

|

1,000,000 |

6,000,000 |

|

1858 |

100,000 |

|

800,000 |

4,480,000 |

|

1859 |

100,000 |

|

500,000 |

2,500,000 |

|

1860 |

2,040,000 |

10,200,000 |

50,000 |

|

|

1862 |

1,673,696 |

10,879,024 |

100,000 |

|

|

1863 |

300,000 |

|

70,000 |

|

|

1873 |

250,000 |

|

600,000 |

|

|

1874 |

130,000 |

|

1,000,000 |

6,000,000 |

|

1875 |

1,000,000 |

|

1,300,000 |

5,580,000 |

|

1876 |

3,500,000 |

24,500,000 |

246,000 |

11,030,000 |

|

1877 |

1,000,000 |

5,500,000 |

220,000 |

|

|

1879 |

2,000,000 |

10,000,000 |

1,350,000 |

7,425,000 |

|

1880 |

800,000 |

|

1,450,000 |

7,612,500 |

|

1881 |

160,000 |

|

850,000 |

5,100,000 |

|

1882 |

406,115 |

|

1,124,000 |

6,182,000 |

* 1 Oqqa = 1.28 kilograms.

** Piastre: 1 English pound was equivalent (1858) to 117-140 Ottoman piastres (qirsh in Arabic and Turkish).

Source: Alexander Schölch, Palestine in Transformation, 1856-1882: Studies in Social, Economic and Political Development (Washington, DC: Institute for Palestine Studies, 1993), 83–84.

Oil Extraction Process

The extraction of oil requires the use of various techniques to obtain good quality and quantity. The first technique involves crushing the olives using a millstone, known as ḥajar al-bad. This process converts the olive into a homogeneous paste, facilitating the pressing process later and extracting oil from it using the pressing technique employed inside the press building. It is worth mentioning here that the crushing technique has survived for hundreds of years, while the pressing techniques to extract the oil have been numerous. When extracting oil, the paste must be spread in wicker baskets, which then are arranged vertically to be pressed two or three times until the last drop of oil is extracted. (See Photos 1 and 3.)

The extracted mixture of olive oil and vegetable water (vegetal liquid mixture) is collected in a pre-prepared vat next to the press (see photo 3). The oil floats on the surface of the mixture, and the olive oil is collected with a ladle. The first press produces the most high-quality and edible (and exportable) oil; the remaining paste or pomace is sprayed with hot water for a second or third squeeze that permits to extract more oil from it called zeit al-'umla. This lower quality oil was sold to soap factories, especially in the city of

Evolution of Oil Extraction Techniques

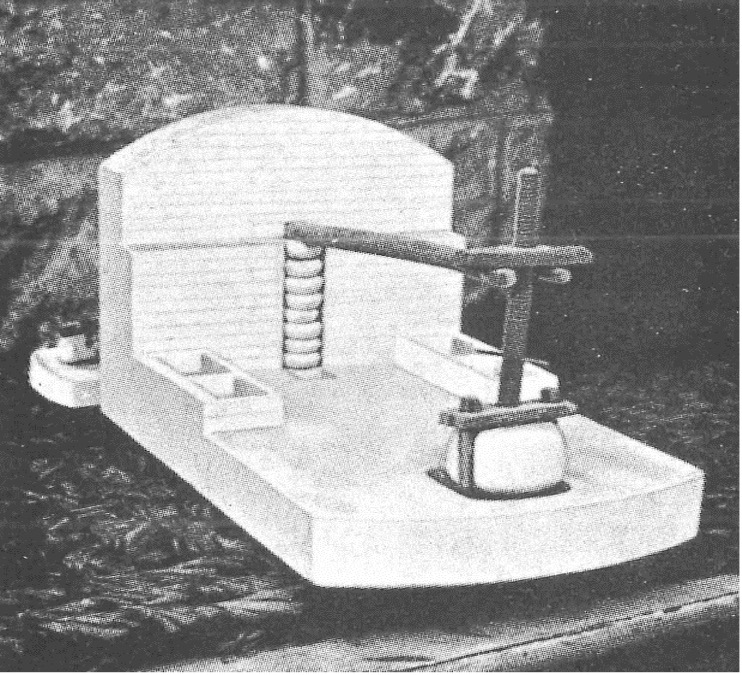

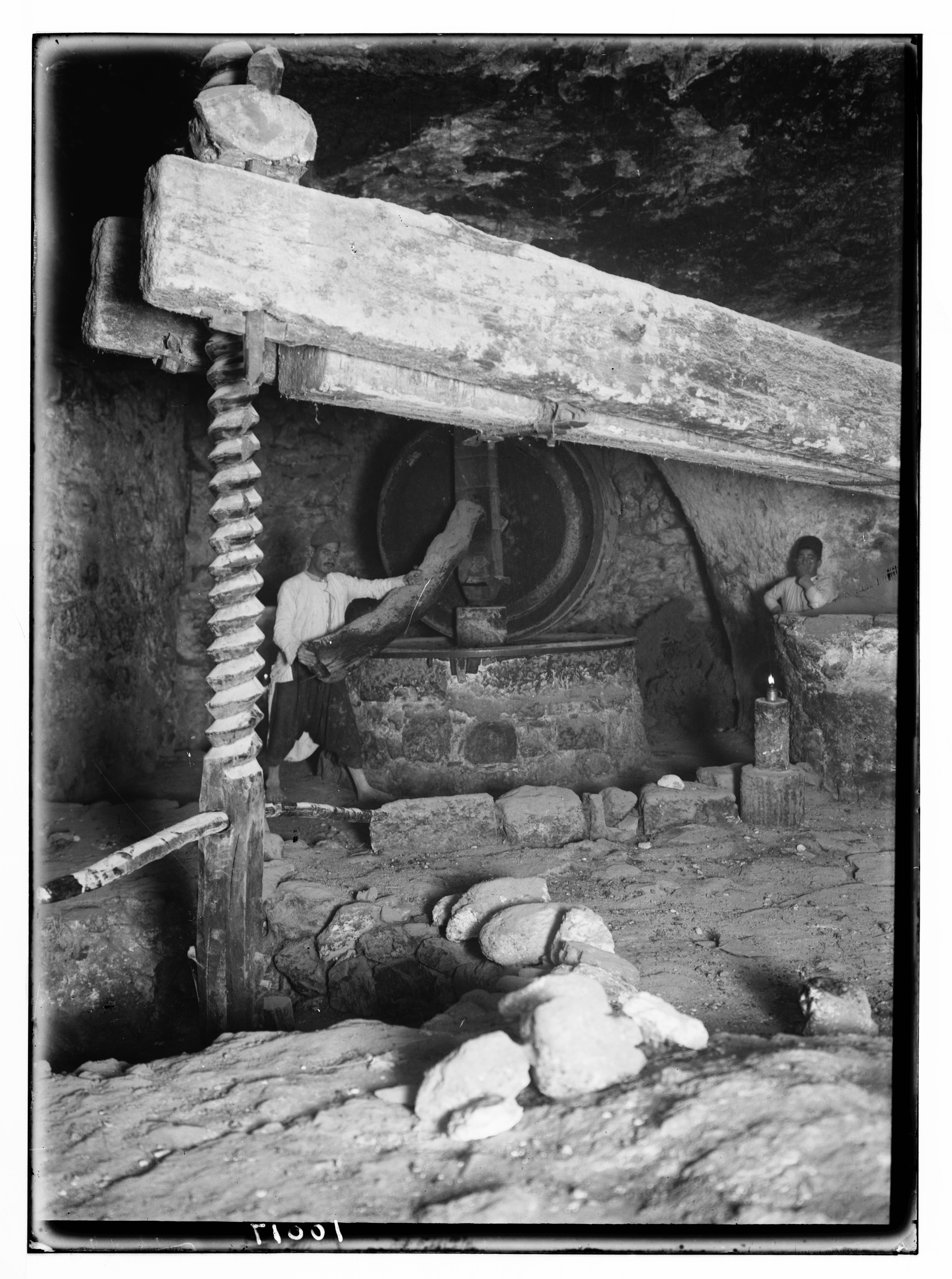

The basic stage of oil extraction requires continuous technical innovations aimed at maximizing the application of pressure on the olive paste through various tools in order to extract the maximum amount of oil from the paste. Until the second half of the nineteenth century, the olive press was done either by using a lever and screw press (photos 1 and 2) or by a wooden screw that exerts direct pressure into the baskets (photo 3). The latter was common especially in the northern regions of Palestine. Since the Palestinian villages considered olive oil one of their most important products, they kept pace with the modern technologies that appeared in Europe, and by the middle of the nineteenth-century they began to adopt the iron presses imported from Europe (photo 4), thus replacing the old techniques that historically relied on local materials (stone and wood) available in the village and its surroundings. Since iron presses allowed twice as much oil as the old techniques to be extracted from the olive paste, wood screw presses practically disappeared in the last decade of the nineteenth century. Iron presses continued to be used in Palestinian villages until 1948.

Iron presses are considered a significant innovation in the range of direct pressing techniques used to extract olive oil. A comparison of the tools shown in photos 3 and 4, which are both direct pressing tools made of either wood or iron, shows that the newer ferrous materials have simply replaced the traditional use of wood. This indicates the continuous evolution of technical processes.

In the "modern" installations documented in Palestine, the screw is operated manually.

Iron presses are proto-industrial machines that do not represent a remarkable technical development in themselves, but rather show how the Palestinian rural community adopted the necessary tools to adapt to technological progress in order to meet the requirements of economic development. Iron presses provide evidence of the technological continuity in olive oil production and the industrial modernization in rural areas that spread in Palestinian villages from the second half of the nineteenth century until the first third of the twentieth century, before the use of automatic engines.

These machines also contributed to the establishment of a tight relationship between the village and the city, which needs olive oil for household consumption and export or for industrial-commercial purposes such as soap production. Economically affluent peasants from the rural middle class who had capital and land resources maintained close ties with merchants and influential families in major Palestinian cities such as Nablus. As a result, these notable families actively supported the acquisition of these machines to ensure a greater supply of olive oil.

Thus, the introduction of iron presses into the village was made possible by the influence of these large merchants and the rural bourgeoisie who owned extensive olive groves in the area. They imported these mills to increase their olive oil production, especially for export and local soap production.

Source: Dalman Gustaf. Arbeit und Sitte in Palästina,

Band 4: Brot, Öl und Wein. Gütersloh: C. Bertelsmann, 1935.

In the background appears a millstone used for olive threshing.

Source: Library of Congress. Matson (G. Eric and Edith)

Photograph Collection.ion

Source: Tamara Lewitt. A Viewpoint on Eastern Mediterranean

Villages in Late Antiquity: Applying the Lens of Community

Resilience Theory. Studies in late Antiquity. vol 4 (2020): 44-75.

Source: Maissoun Sharkawi, 2012.

Import and Manufacture of Manual Iron Screw Presses

Unlike other olive oil extraction elements that could be made and supplied within the village, the iron press was made outside the village. The machines were first introduced through the main port of Jaffa from olive oil producing countries that bordered the Mediterranean, mainly from Piraeus in Greece (Vasiliadhis presses) and Aix-en-Provence in France (Victor Coque presses). However, the other two documented models were replicas of previously imported ones and were produced in the industrial city of Jaffa, mainly at the Leon Stein factory (1890), the Wagner Brothers factory (1895), and the Palestine Iron and Brass Foundry (1931).

The “locally made” iron presses, mainly those reproduced by Leon Stein or the Wagner Brothers, were more in demand, and were probably the most widespread from the time they were produced around 1890 onwards; whatever their price, they must have been cheaper than the presses imported from southern France or Greece.

According to

Avitsur, Shmu’el. “Olive Oil Production in the Land of Israel: Traditional to Industrial.” In Rafael Frankel, Shmuel Avitsur and Etan Ayalon, eds., History and Technology of Olive Oil in the Holy Land. Arlington, VA: Olearius Editions, 1994.

Brun, Jean-Pierre. Le vin et l'huile dans la Méditerranée antique: viticulture, oléiculture et procédés de transformation. Paris: Errance, 2003.

Doumani, Beshara. Rediscovering Palestine: Merchants and Peasants in Jabal Nablus, 1700-1900. Berkeley: University of California Press, 1995.

Gilbar, Gad. Ottoman Palestine, 1800-1914: Studies in Economic and Social History. Leiden: E. J. Brill, 1990.

Nashif, Khaled. Olive Presses in Palestine. Irbid: Yarmouk University, 2009. (in Arabic)

Sharkawi, Maissoun. Iron Screw Presses with Manual Activation of the 19th Century as an Object of Heritage, in the Context of the Palestinian Cultural Heritage. Nancy: Université de Lorraine, 2018 (doctoral dissertation).

Warnock, Peter. Identification of Ancient Olive Oil Processing Methods Based on Olive Remains. Oxford: Archaeopress, 2007.

Weinryb, Bernard. “Industrial Development of the Near East.” The Quarterly Journal of Economics 61, no.3 (1947): 471–99.